What Makes Terminal Boxes Vital for Modern Electrical Systems?

In the fast-evolving world of industrial and commercial electrical installations, terminal boxes have become a cornerstone of safe, efficient, and organized wiring. Terminal boxes, also known as junction boxes, serve as enclosures where electrical connections are safely housed, ensuring the protection of both the wiring system and personnel. With the increasing complexity of electrical networks, understanding the advantages, functionalities, and future trends of terminal boxes is critical for engineers, contractors, and facility managers.

What Are the Core Advantages of Using Terminal Boxes?

Terminal boxes offer multiple advantages that are indispensable for electrical infrastructure:

-

Enhanced Safety: Terminal boxes protect electrical connections from accidental contact, reducing the risk of electric shock and fire hazards. By enclosing wires, terminals, and connectors, they maintain compliance with global safety standards.

-

Organization and Accessibility: A terminal box provides a centralized location for multiple wiring connections, making troubleshooting, maintenance, and upgrades more efficient. Organized wiring reduces downtime and the risk of errors during modifications.

-

Durability and Environmental Protection: High-quality terminal boxes are designed to resist dust, moisture, and chemical corrosion. Many models conform to IP standards (IP65, IP66), ensuring that electrical connections remain secure even in harsh industrial environments.

-

Scalability for Complex Systems: Terminal boxes are available in various sizes and configurations, allowing for the expansion of electrical systems without extensive rewiring. This flexibility is crucial for modern industrial plants, commercial buildings, and renewable energy installations.

-

Aesthetic and Space Efficiency: In addition to functional benefits, terminal boxes contribute to a cleaner and more compact wiring layout, avoiding cluttered panels and open junctions. This not only improves safety but also enhances the professional appearance of installations.

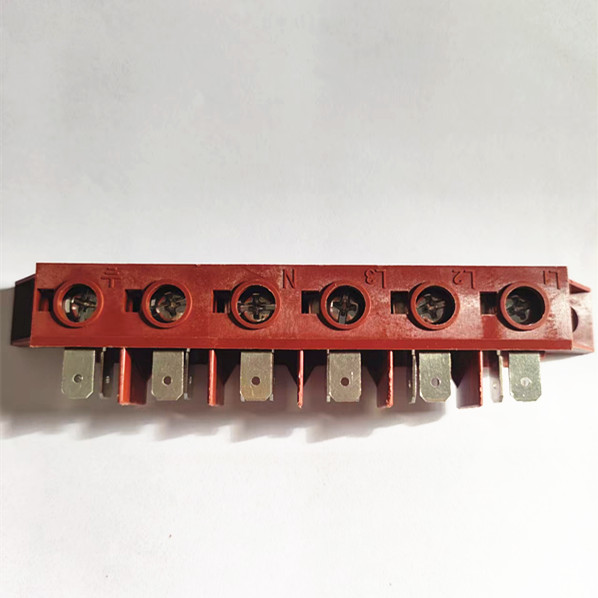

Product Specifications

A professional terminal box should be selected based on clear technical parameters to ensure compatibility and long-term reliability. Below is a reference table summarizing standard specifications:

| Parameter | Typical Value / Description |

|---|---|

| Material | ABS, PVC, Stainless Steel, Aluminum |

| Protection Level (IP Rating) | IP54, IP65, IP66 |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Wall-mounted, Surface-mounted, Din-rail Compatible |

| Dimensions | Customizable, Common sizes: 100x100x60mm to 500x500x200mm |

| Cable Entry Points | Pre-drilled knockout holes or customizable openings |

| Color Options | Grey, White, Black, Transparent Lid |

| Accessories | Terminal strips, grounding bars, sealing gaskets |

The choice of material, protection level, and size should align with the operational environment, whether indoors or outdoors, standard or corrosive conditions.

How Do Terminal Boxes Enhance Electrical System Functionality?

Terminal boxes are more than protective enclosures—they play a crucial role in the efficiency and reliability of electrical systems. Understanding their functional aspects helps in designing more effective installations.

-

Wire Management and Distribution: Terminal boxes provide a structured interface where multiple circuits converge. They allow for organized wiring layouts, color-coded connections, and clear labeling, which improves maintenance efficiency and reduces the likelihood of errors.

-

Electrical Isolation and Safety Compliance: By separating live wires from each other and from the external environment, terminal boxes prevent short circuits, overloads, and accidental shocks. They also ensure adherence to national and international electrical codes, including IEC and NEC standards.

-

Simplified Troubleshooting: When electrical faults occur, terminal boxes allow technicians to access and test individual circuits without dismantling entire systems. This reduces downtime and increases operational reliability.

-

Adaptability for Automation and Smart Systems: Modern terminal boxes are designed to accommodate smart components such as sensors, relays, and IoT modules. This makes them suitable for advanced industrial automation systems and renewable energy applications.

-

Thermal Management: Many terminal boxes include ventilation options or heat-dissipating materials to prevent overheating in high-current circuits, thereby extending the lifespan of connected devices.

Why Material and Design Choices Matter

-

ABS and PVC: Lightweight, cost-effective, corrosion-resistant; ideal for indoor use.

-

Stainless Steel and Aluminum: Robust, high-temperature resistance, suitable for industrial environments and outdoor installations.

-

IP Rating Selection: IP65 or above is recommended for outdoor or dusty environments, while IP54 may suffice indoors.

By selecting the right material, size, and IP rating, terminal boxes can seamlessly integrate into a variety of electrical systems while maintaining safety, efficiency, and longevity.

Why Are Terminal Boxes Essential for Future Electrical Infrastructure?

The role of terminal boxes continues to evolve as electrical and industrial systems become more sophisticated. Understanding these trends helps businesses make future-ready investments.

-

Integration with Renewable Energy Systems: With the global push for solar, wind, and hybrid energy systems, terminal boxes are increasingly designed to handle higher voltages, variable currents, and weather-exposed installations.

-

Support for Smart Grid and IoT Applications: Terminal boxes are adapting to smart grids by accommodating sensors, communication modules, and monitoring devices. They enable real-time system diagnostics, predictive maintenance, and energy optimization.

-

Compliance with Advanced Safety Standards: Emerging electrical safety regulations require enhanced enclosure designs to minimize fire risks, provide better grounding options, and resist environmental hazards. Terminal boxes are evolving to meet these standards.

-

Customization and Modular Designs: As electrical systems become more complex, terminal boxes offer modular designs that allow easy expansion or reconfiguration without extensive rewiring. This reduces project costs and installation time.

-

Sustainability and Material Innovation: Eco-friendly materials and recyclable plastics are being incorporated into terminal box production, aligning with the global shift toward greener industrial solutions.

Common Applications

-

Industrial manufacturing facilities

-

Renewable energy installations (solar, wind)

-

Commercial buildings and data centers

-

Automation and robotics systems

-

HVAC and lighting systems

The adaptability and resilience of terminal boxes ensure they remain relevant as industrial and commercial infrastructure becomes more sophisticated and environmentally conscious.

Terminal Box FAQs: What, Why, and How

Q1: What factors should be considered when selecting a terminal box?

A1: Selection depends on material, IP rating, size, and mounting type. Environmental conditions (indoor/outdoor, humidity, temperature) and electrical requirements (voltage, current, number of connections) must guide the choice. Ensuring compatibility with national and international safety standards is essential.

Q2: How can a terminal box improve system maintenance efficiency?

A2: Terminal boxes centralize wiring connections, provide clear labeling, and allow easy access to circuits. This structure simplifies troubleshooting, testing, and modifications, reducing downtime and operational costs.

Q3: Why are IP ratings critical for terminal boxes?

A3: IP ratings indicate protection against dust and water ingress. Selecting the correct IP rating ensures the terminal box can withstand environmental conditions, preventing damage to connections, reducing maintenance frequency, and prolonging lifespan.

Terminal boxes are a fundamental component of modern electrical systems, combining safety, organization, and adaptability. Their evolving design addresses the growing demands of industrial automation, renewable energy, and smart infrastructure, making them indispensable for engineers and facility managers. Choosing the right terminal box requires careful consideration of material, IP rating, dimensions, and mounting type, ensuring long-term reliability and compliance with safety standards.

CMZG offers high-quality terminal boxes tailored to diverse industrial and commercial applications, ensuring protection, efficiency, and future-ready solutions. For more information or to discuss specific requirements, contact us today to explore our full range of terminal box solutions.